Great strength of Produform, introduced in 2003 to fill the market’s need to obtain samples for functional tests, our Rapid Tooling RP Produtool system allows our customers to test parts in the definitive thermoplastic material in a much faster time than the time required for the construction of the definitive multi-impression molds, to the point that many mold makers use our service in partnership to obviate the increasingly tight delivery times required by the global market.

Aluminum molds have the advantage of good workability in the workshop and allow the production of identical injection-molded series in materials and process to the same end products in all limited thermoplastic materials.

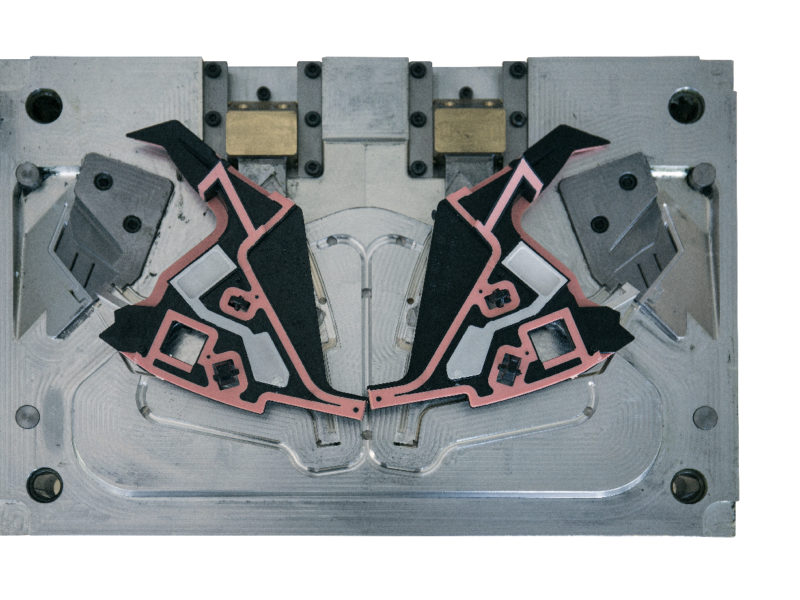

We routinely manage products made by lateral movements (trolleys) and faithfully respect the geometry that the customer supplies us without compromising.

We manage the entire development phase and changes that are normal in the Product Development phase.

We have in our Tool Shop department all the main CNC machine tools (Computer Numerical Control) such as Milling, Turning, Erosion and Wire, Micro-drilling and Laser Welding Work Centers to make the molds completely and independently